Yeast Cell Disruption

Note: With yeast cells that require higher pressures, there is often a balance between using higher pressure for more cell lysis in a single pass and multi-passing at lower pressure. Higher pressure results in higher temperature, which may sometimes be detrimental to protein recovery. Our cooling systems can counteract this. We can advise you on HPH processing parameters for your application. The before and after processing images below demonstrate the high lysis efficiency our STANSTED homogenizers can achieve.

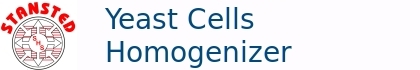

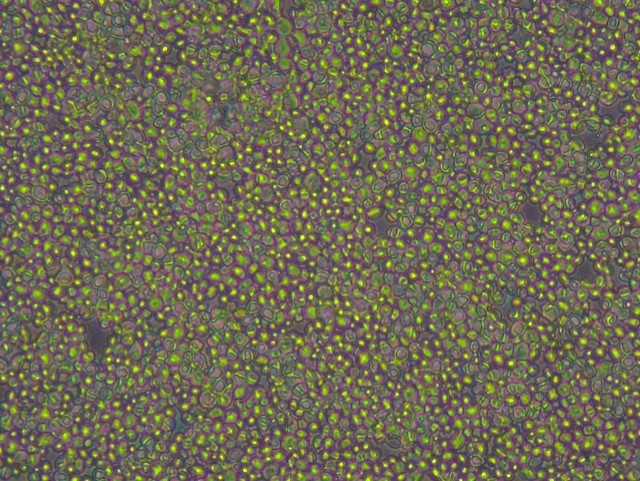

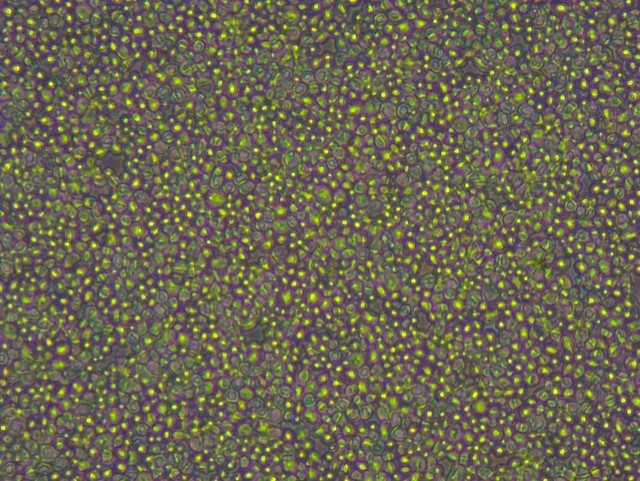

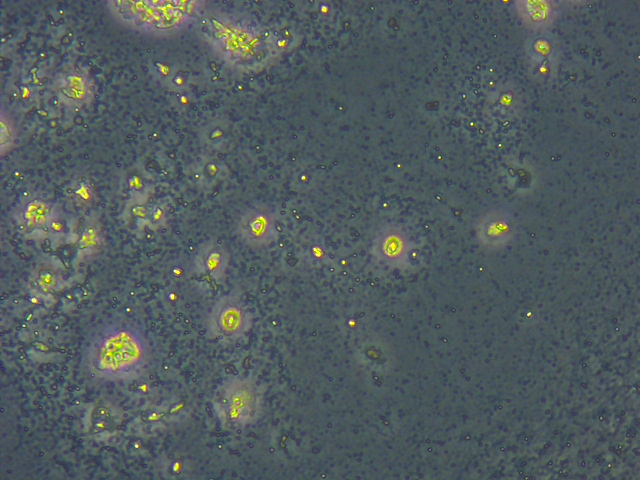

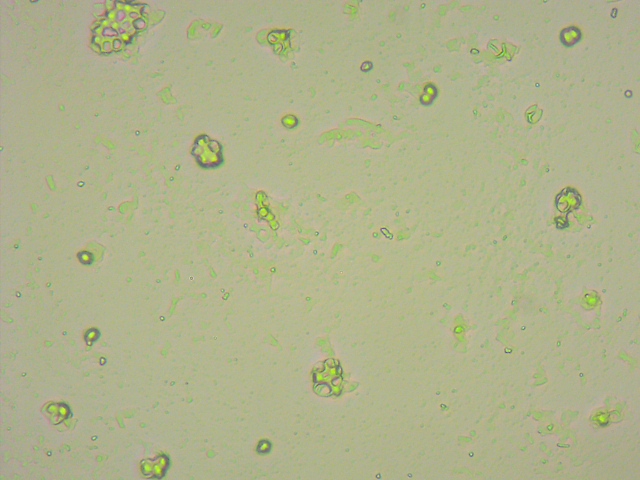

The before and after processing images below demonstrate the high lysis efficiency our STANSTED homogenizers can achieve.

Fig A, B - Unprocessed Yeast suspension.

Fig C, D, E - Processed Yeast suspension, after Cell Disruption, using different processing conditions.

Fig A

Fig B

Fig C

Fig D

Fig E

Yeast Cells - Benefits of our Technology

![]() Process pressures from 1,500 psi (100 bar) to 60,000 psi (4200 bar) - the highest available for this technology.

Process pressures from 1,500 psi (100 bar) to 60,000 psi (4200 bar) - the highest available for this technology.

![]() Multiple options for temperature control including pre-heating and rapid post process cooling.

Multiple options for temperature control including pre-heating and rapid post process cooling.

![]() Process volumes from 1m to 275ml per minute in the Lab -> 16 l/h to 130 l/h to 2000 l/h at production scale.

Process volumes from 1m to 275ml per minute in the Lab -> 16 l/h to 130 l/h to 2000 l/h at production scale.

![]() Easy to maintain, clean - CIP and SIP - and lower ongoing operating costs due to the high reliability of our technology.

Easy to maintain, clean - CIP and SIP - and lower ongoing operating costs due to the high reliability of our technology.

![]() HPH pretreatment can accelerate S. cerevisiae yeast autolysis which may result in higher protein, amino acid and total solids yield.

HPH pretreatment can accelerate S. cerevisiae yeast autolysis which may result in higher protein, amino acid and total solids yield.

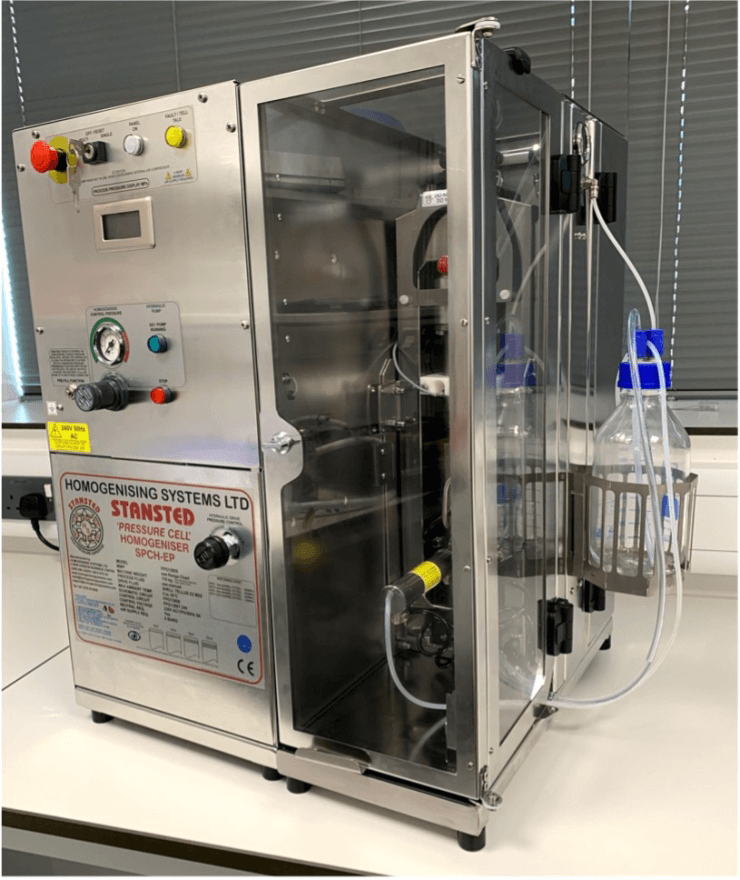

Production Scale

Lab Scale Cell Disruptor - modern 'French Press' type.

Please get in touch to discuss your requirements.

European CE and other international safety standards compliant construction.