Our systems are designed to meet the unique requirements of the Pharmaceutical, Biotechnology, Nutraceuticals, and Chemical processing sectors. This includes 'Clean in Place' (CIP) and 'Steam in Place' (SIP) capabilities.

Two models are in our Pilot Homogenizer range, each providing different processing options.

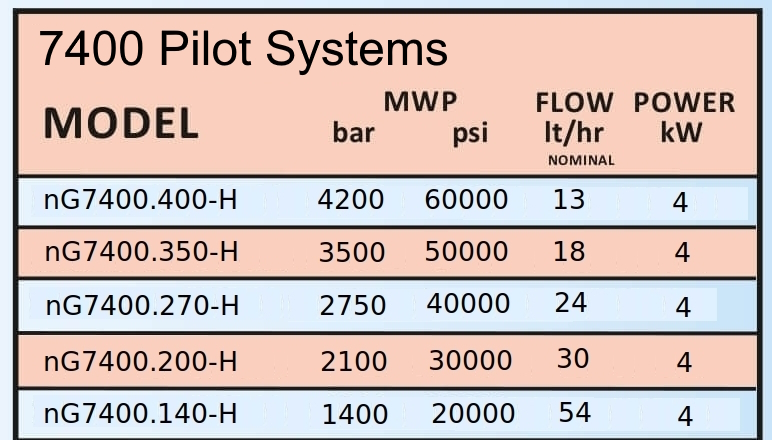

![]() 7400 systems - these sit between our Lab Homogenizers and the larger volume Pilot 7575 models. The 7400s offer flow rates of between 13 l/h and 54 l/h.

7400 systems - these sit between our Lab Homogenizers and the larger volume Pilot 7575 models. The 7400s offer flow rates of between 13 l/h and 54 l/h.

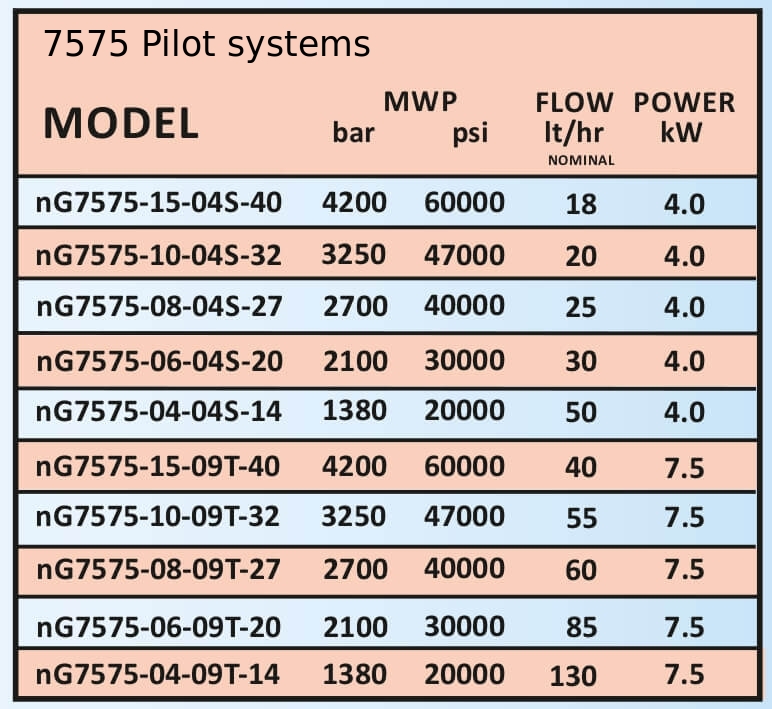

![]() 7575 systems provide higher volumes of up to 130 l/h. To increase volumes further, click 'Production' on the main menu.

7575 systems provide higher volumes of up to 130 l/h. To increase volumes further, click 'Production' on the main menu.

The 7575 series comes with a PLC with an HMI and touch-screen interface and is designed to comply with cGMP and FDA-GMP. It can be offered with IQ / OQ documentation and materials certification.

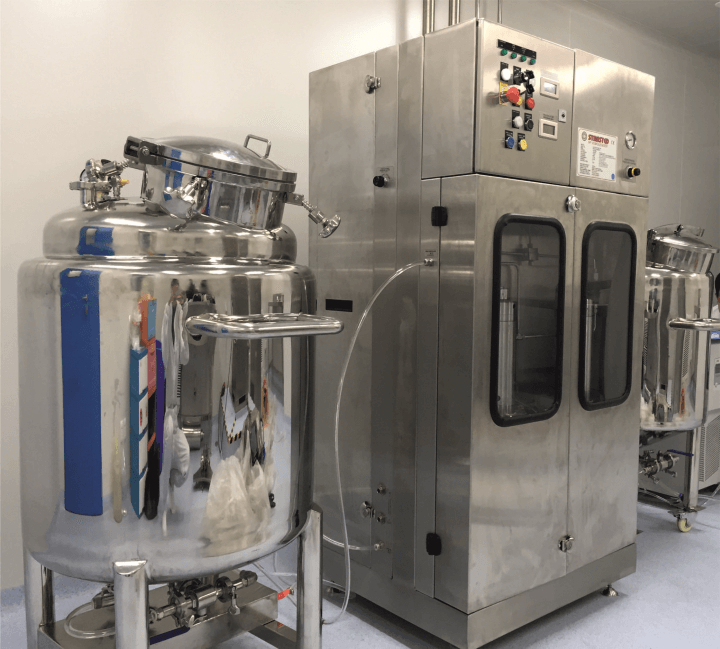

7575 Pilot Homogenizer in a pharmaceutical application with feed and discharge reservoirs

Our Pilot Homogenizers - features and advantages:

![]() Single and twin intensifier versions are available for continuous high-shear fluid processing operation at working pressures up to 60,000 psi / 4200 bar and process volumes up to 125 l/h.

Single and twin intensifier versions are available for continuous high-shear fluid processing operation at working pressures up to 60,000 psi / 4200 bar and process volumes up to 125 l/h.

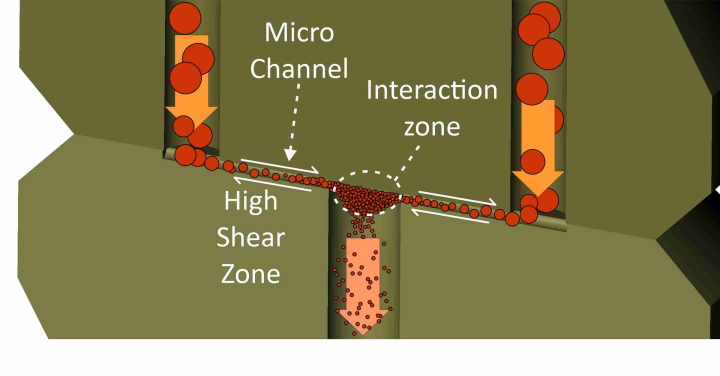

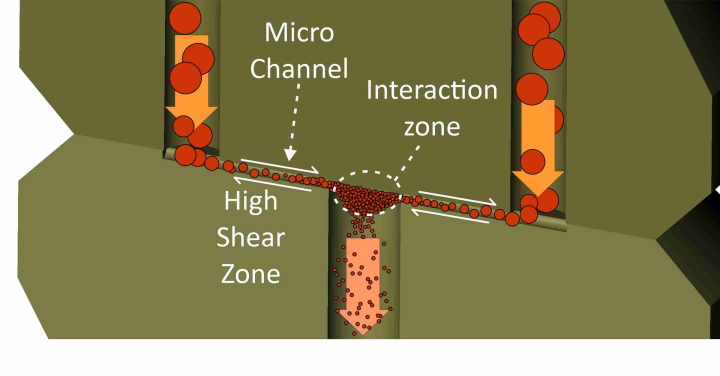

![]() Micro-channel (interaction chambers) and piston gap processing configurations (or both) for optimized processing to match the application.

Micro-channel (interaction chambers) and piston gap processing configurations (or both) for optimized processing to match the application.

![]() Temperature control includes multiple heat exchanger options for system inlet, in-process, and outlet post-process.

Temperature control includes multiple heat exchanger options for system inlet, in-process, and outlet post-process.

![]() System control is provided through a dedicated PLC with HMI and a touchscreen interface with integral data logging of primary process parameters.

System control is provided through a dedicated PLC with HMI and a touchscreen interface with integral data logging of primary process parameters.

![]() Documentation packs include the provision of DQ/IQ/OQ.

Documentation packs include the provision of DQ/IQ/OQ.

![]() 'Clean-in-Place' (CIP) and 'Steam-in-Place' (SIP) capability.

'Clean-in-Place' (CIP) and 'Steam-in-Place' (SIP) capability.

![]() Easy to use and maintain, high operating reliability ensures lower ongoing operating costs than other systems.

Easy to use and maintain, high operating reliability ensures lower ongoing operating costs than other systems.

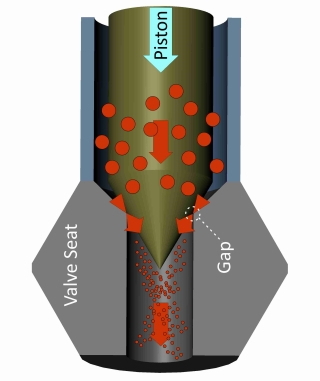

Homogenizing valves - Piston Gap and Micro-Channel Device (interaction chamber).

STANSTED Homogenizers are unique in that they can be fitted and operated with multiple processing heads, including Piston Gap valves, Micro Channels, and fixed orifice processing heads. This processing versatility allows users of STANSTED equipment to work with a broader range of applications, cell types, and materials.

Another unique benefit of STANSTED processing heads is that they can be customised for individual applications, resulting in superb process optimisation.

STANSTED ‘Reverse flow’ Piston Gap valves use specially formulated ceramics for wear resistance. They can be easily inspected and refurbished and are unlikely to experience blockages. Piston gap technology can be used for multiple applications, with cell lysis (disruption) being the most common.

STANSTED Micro Channels (similar to ‘Interaction Chambers’) are fitted with polycrystalline diamond (PCD) wear elements that can be easily dismantled for inspection, cleaning, and refurbishment. Additionally, the PCDs can be changed for alternative channel configurations. Micro Channels can be used for multiple applications, with particle size reduction being the most common.

Please get in touch to discuss your requirements.