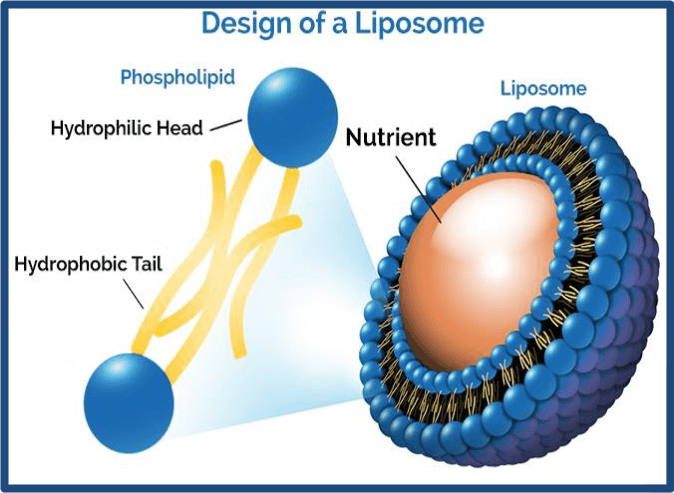

A liposome is a spherical vesicle with a membrane composed of a phospholipid bilayer that delivers a drug or genetic material into a cell.

Liposomes can be composed of naturally derived phospholipids with mixed lipid chains like egg phosphatidylethanolamine or pure components like dioleoyl phosphatidylethanolamine.

Our High-Pressure Homogenizer systems for the Preparation of Liposomes

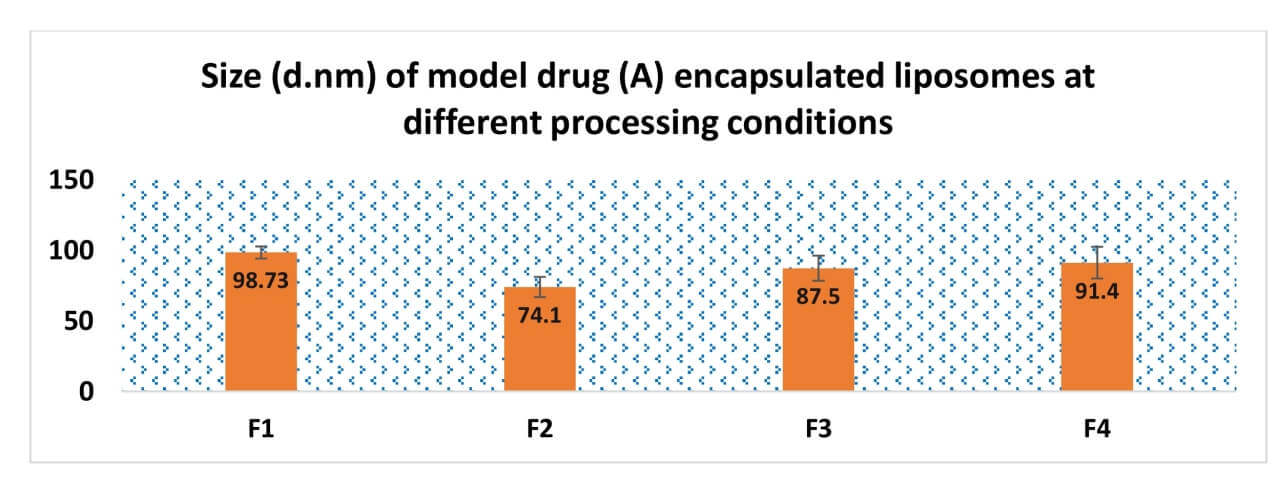

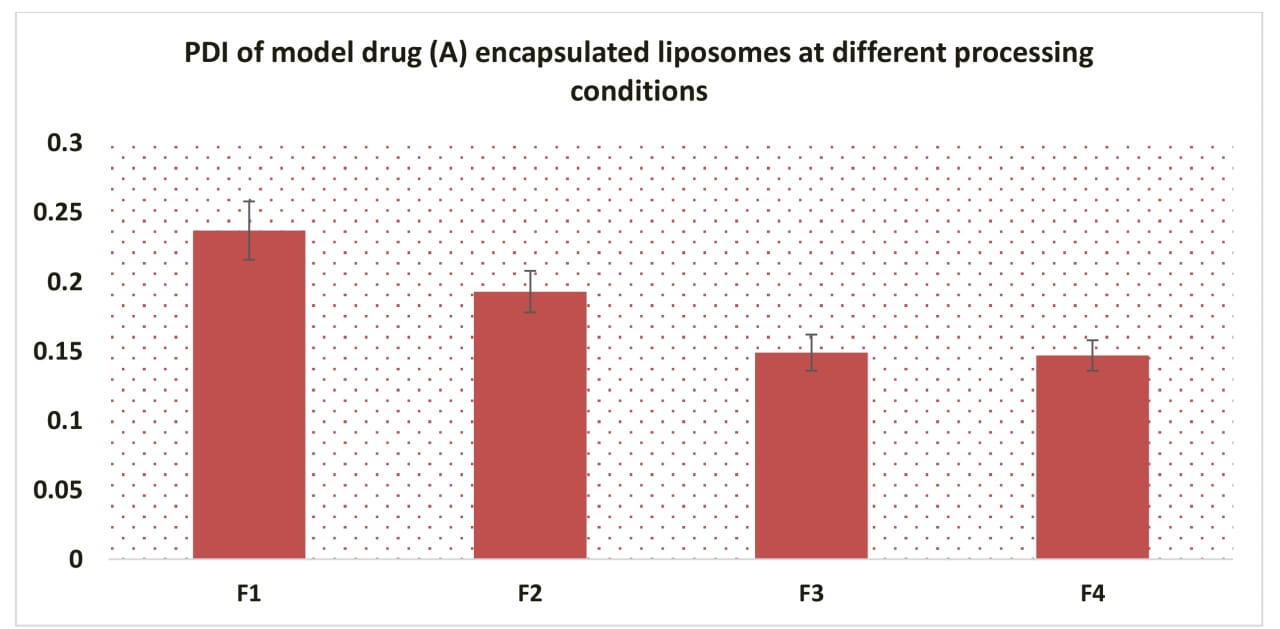

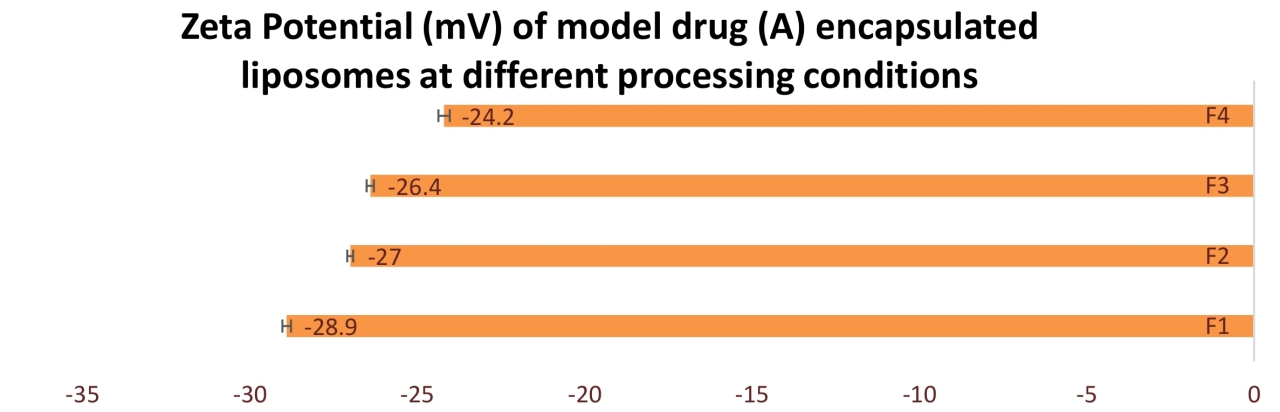

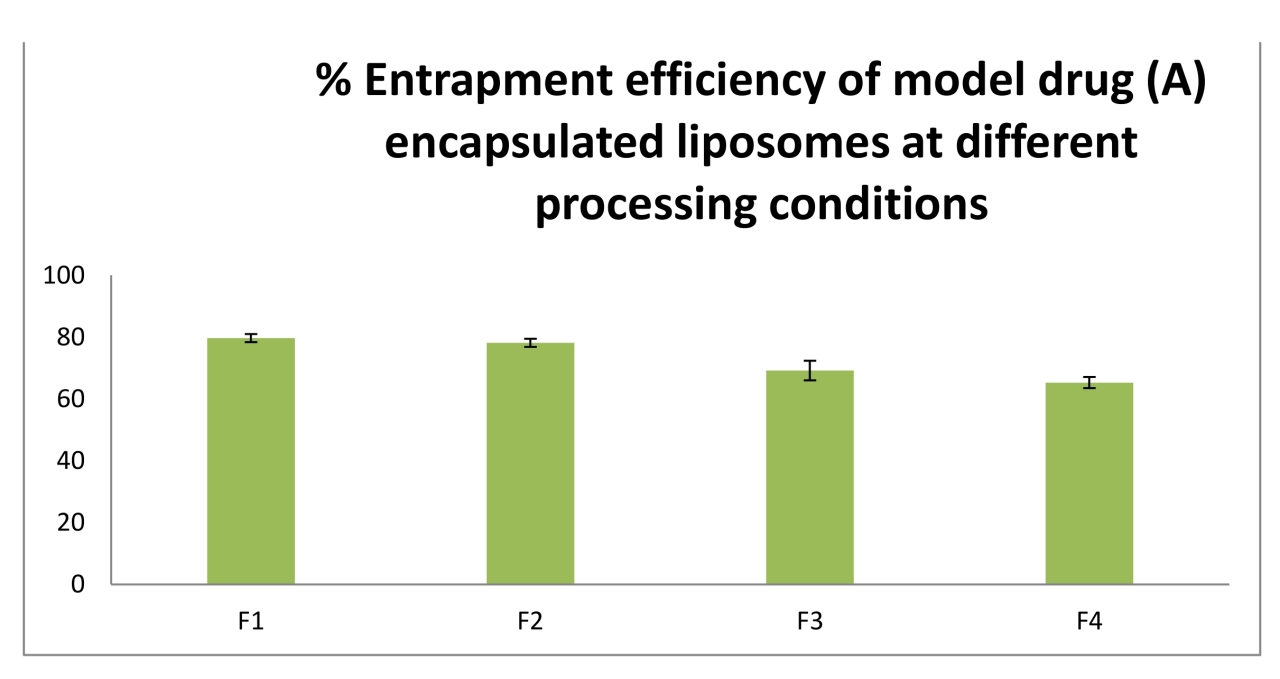

Our Application Specialists have undertaken multiple liposomal formulation trials. Liposomes loaded with hydrophilic and hydrophobic drugs were formulated and assessed for particle size and Polydispersity Index (PDI).

The results were very positive, as many of our customers have also discovered the benefits of utilizing our technology over the years.

Using our unique technology, different processing parameters were used during these tests, including various high pressures, the number of passes through our homogenizer, and different processing heads—both piston gap valves (PG) and our micro-channel devices (MCD). Sizes from the micron level to below 50 nanometers/nm can be achieved.

In most scenarios, particle sizes and the polydispersity index can be reduced by processing at different pressures and/or increasing the number of passes through the homogenizer.

STANSTED High-Pressure Homogenizers - features and advantages

![]() Provide rapid vesicle size and lamellarity reduction to achieve smaller sizes whilst narrowing the distribution .

Provide rapid vesicle size and lamellarity reduction to achieve smaller sizes whilst narrowing the distribution .

![]() HPH also allows the loading of the Liposomes, locating hydrophilic active substances within the aqueous vesicle core..

HPH also allows the loading of the Liposomes, locating hydrophilic active substances within the aqueous vesicle core..

![]() Ultra-high pressures to 60,000 psi (4200 bar) and processing from 1 ml to 35ml in the Laboratory up to flow rates in excess of 2000 l/h.

Ultra-high pressures to 60,000 psi (4200 bar) and processing from 1 ml to 35ml in the Laboratory up to flow rates in excess of 2000 l/h.

![]() Easy to scale - from Lab to complete production systems for continuous processing with repeatable results.

Easy to scale - from Lab to complete production systems for continuous processing with repeatable results.

![]() Multiple options for temperature control, including pre-heating and rapid post-process cooling..

Multiple options for temperature control, including pre-heating and rapid post-process cooling..

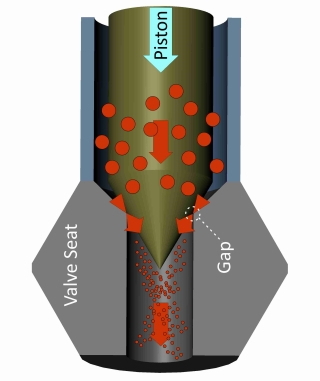

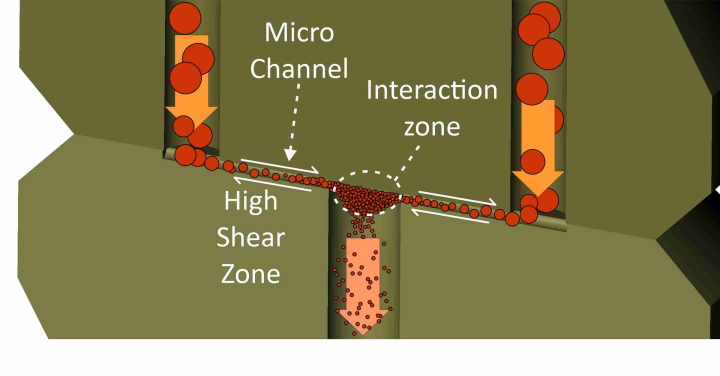

Piston Gap and Micro-Channel Device (interaction chamber).

Our company is unique in that we offer interchangeable piston gap (PG) and micro-channel devices (MCD) processing heads for systems. For Liposome preparation, both types can be effective, but we recommend (for production applications) that both technologies be tested.

Vesicle size reduction is a function of pressure, valve type (PG or MCD) and formulation. Typically, sizes from micron level to below 50 nanometers / nm can be achieved.

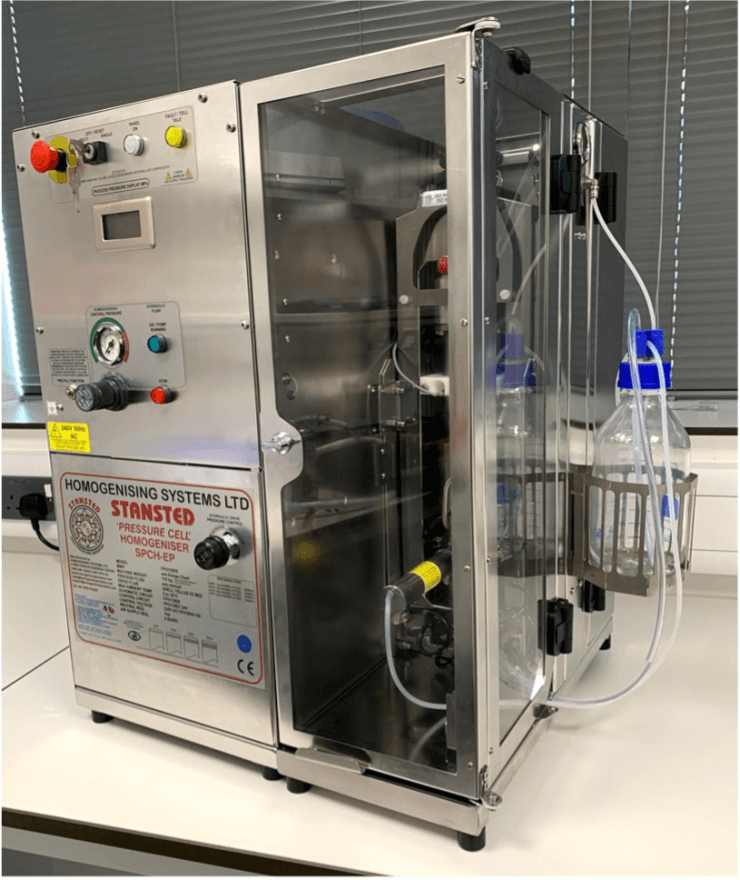

Highly versatile, fully featured bench top instruments with pressures to 60,000 psi (410 MPa, 4200 bar).

For R&D and smaller scale production up to 125 l/h.

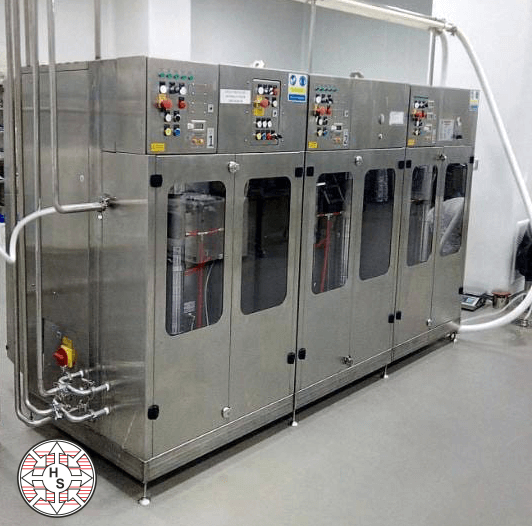

Full scale production systems with flow rates up to 2000 l/h offering unrivalled performance.