Nanocellulose

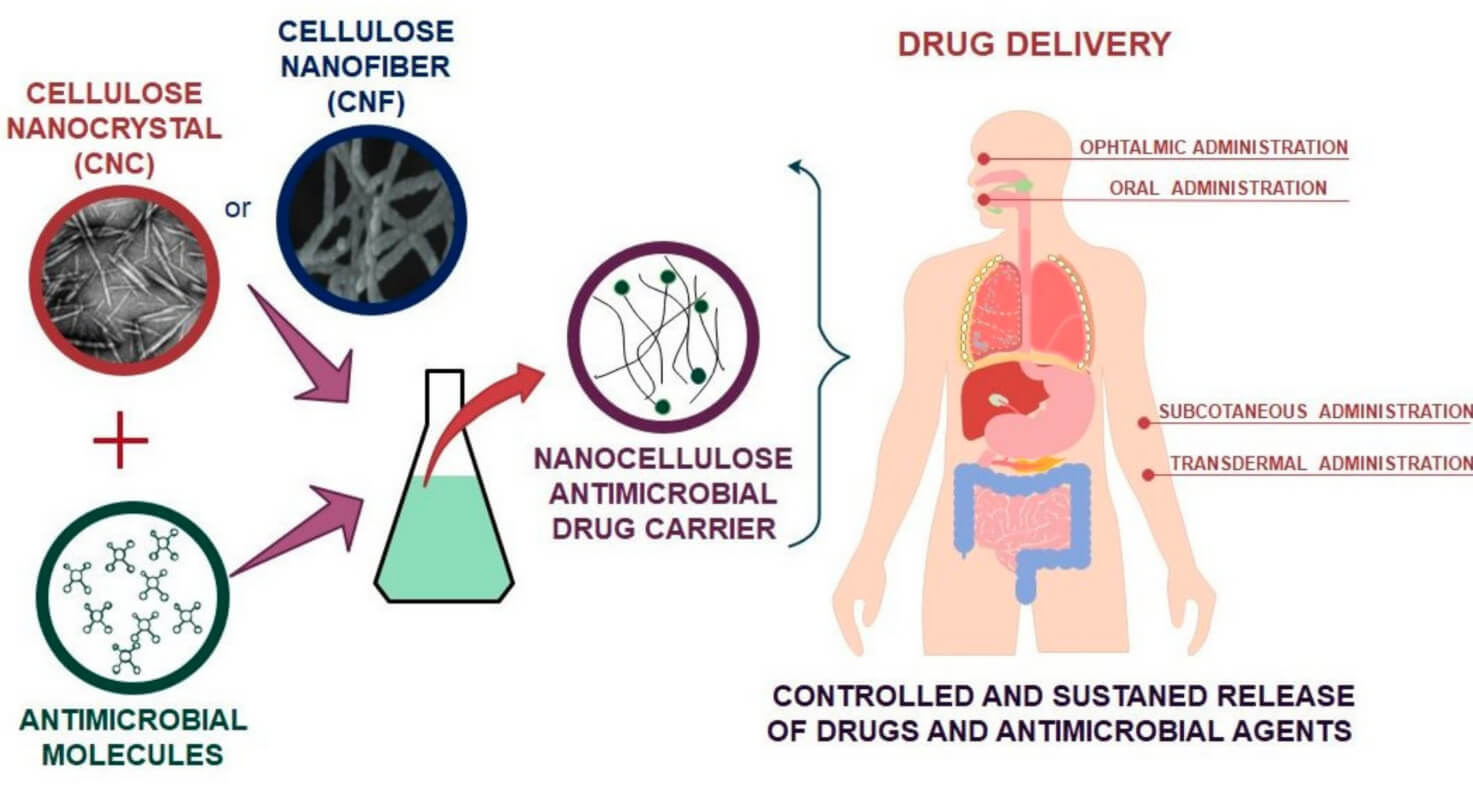

Nanocellulose is nanostructured cellulose, often as nanocellulose crystals (NCC) or nanocellulose fibres (CNF / NCF).

Nanocellulose is a nanomaterial with a high specific surface area, surface energy, and strength. It is non-toxic, non-hazardous, biocompatible, and environmentally beneficial and can be extracted from various biomass resources.

It has a high specific surface area and strength. It is biocompatible, biodegradable, and can be extracted from various biomass resources. Nanocellulose has multiple applications in many sectors, including pharmaceutical, medical, material engineering and cosmetics.

Benefits of our class-leading High Pressure Technology

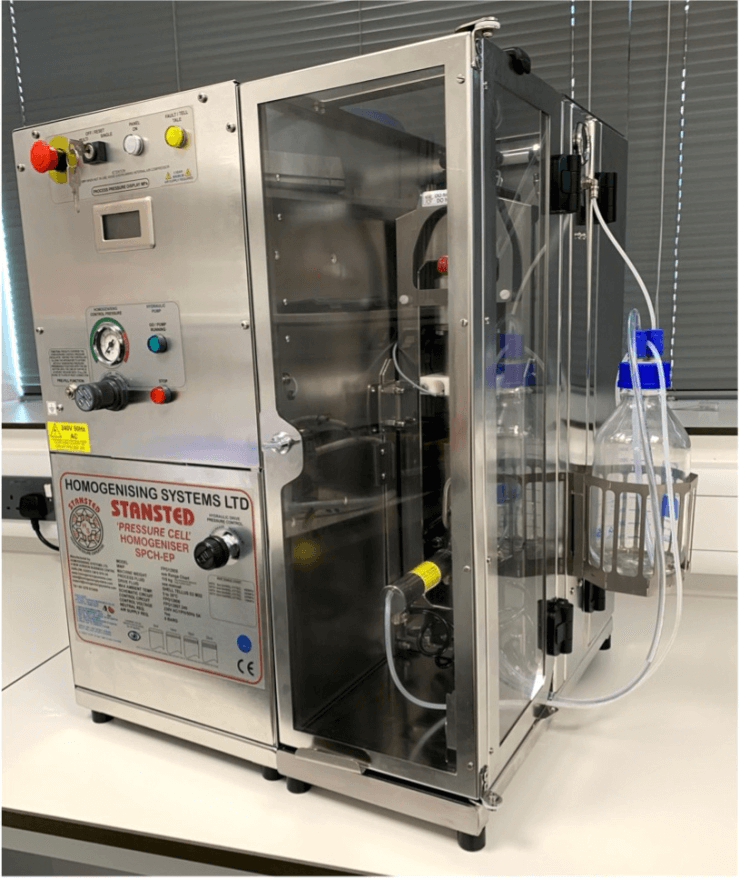

![]() Easy-to-scale systems capable of producing Nanocellulose products at an industrial scale.

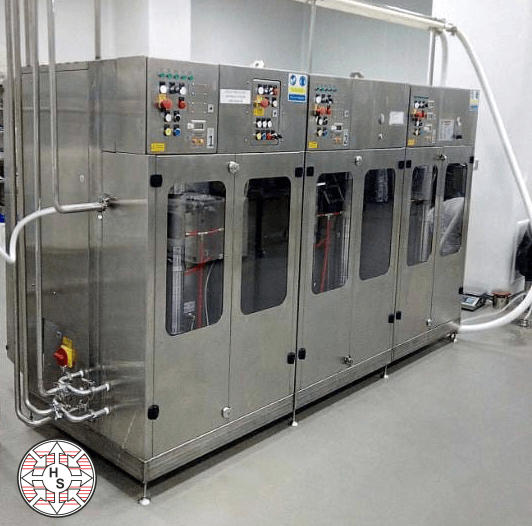

Easy-to-scale systems capable of producing Nanocellulose products at an industrial scale.

![]() Ultra high-pressures up to 60,000 psi (4200 bar) and processing from Lab sample sizes to flow rates over 1000 l/hour.

Ultra high-pressures up to 60,000 psi (4200 bar) and processing from Lab sample sizes to flow rates over 1000 l/hour.

![]() Utilising high-shear to create ultra-fine nanofibers whilst maintaining the original length.

Utilising high-shear to create ultra-fine nanofibers whilst maintaining the original length.

![]() Well-dispersed fibres with exceptional strength properties.

Well-dispersed fibres with exceptional strength properties.

![]() Smaller particle sizes, with narrow distributions, when compared to other techniques.

Smaller particle sizes, with narrow distributions, when compared to other techniques.

![]() Our unique technology and slower pump speed lessen the risks of solid accumulation in the homogenizer.

Our unique technology and slower pump speed lessen the risks of solid accumulation in the homogenizer.

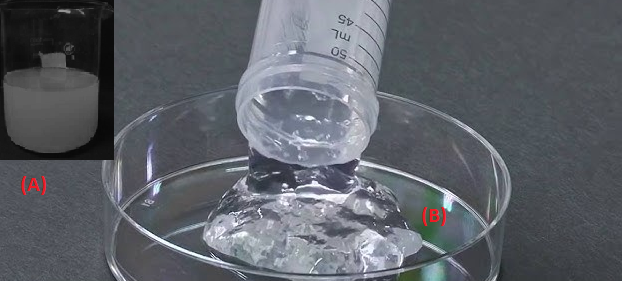

After processing using our Lab R&D Homogenizer

Cellulose Fibers before processing (A) and after (B)

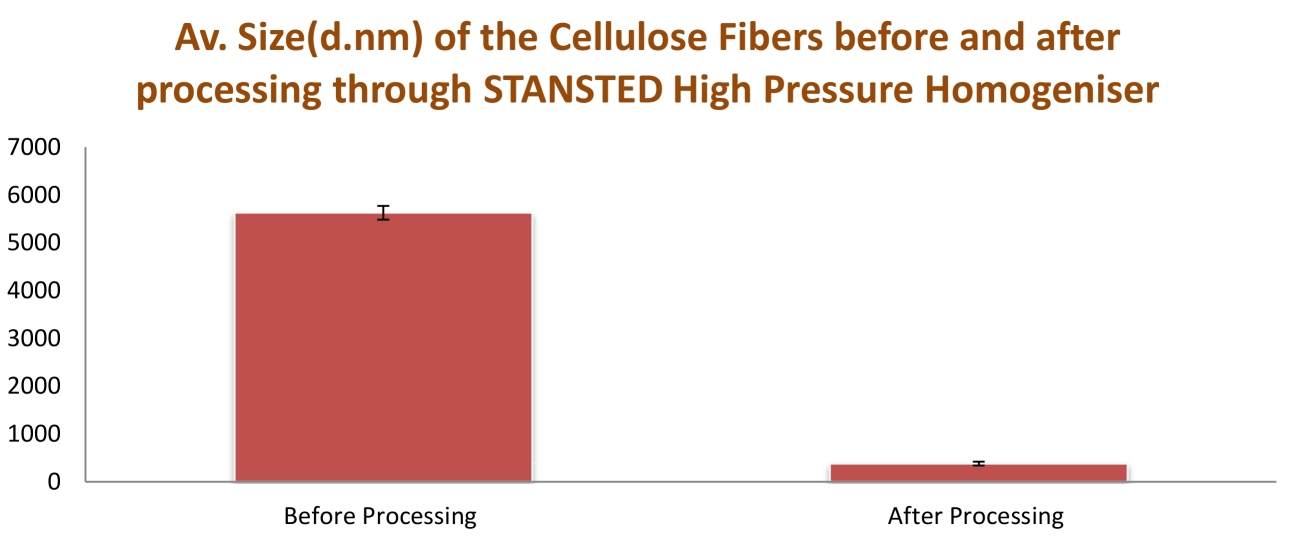

Data from our research using our STANSTED High-Pressure Homogenizers.

Samples in the form of slurry, usually prepared in deionized water, were passed through piston gap (PG) and micro-channel devices (MCD) processing heads.

The number of passes required depended on multiple factors, including the type of nanocellulose and pre-treatment processes.

Our industry-leading technology provided excellent results in most scenarios.

The processing of Nanocellulose Crystals (NCC) provided exceptional results.

Whatever procedures you opt for to process your nanocellulose samples, our unique technology can play an essential part in your research and production.

Small scale for R&D. Versatile and easy to use. Ultra high pressures to 60,000 psi (4200 bar).

Process volumes to 125 lt/hr for smaller scale production.

Process volumes to 1000 lt/hr (264 US Gallons). Unrivalled performance.

Please get in touch to discuss your requirements.

Nanocellulose is also referred to as:

CNF - cellulose nanofibers.

CNC or NCC - cellulose nanocrystal.

NFC - Nanofibrillated cellulose.

MFC - Microfibrillated cellulose.