Nanoemulsions are kinetically stable liquid-in-liquid dispersions with droplet sizes between 20 and 500 nm that require high energy to be efficiently created.

Our high-pressure, high-shear technology has advantages over other nanoemulsion formulation methods, including sonication techniques.

Nanoemulsions - STANSTED High-Pressure Homogenizers

![]() Enabling sterile filtration, especially in the pharmaceutical industry - e.g. for Vaccine adjuvant.

Enabling sterile filtration, especially in the pharmaceutical industry - e.g. for Vaccine adjuvant.

![]() With the best particle size control - from nm to μm - producing stable, uniform particle sizes improves product bioavailability and stability.

With the best particle size control - from nm to μm - producing stable, uniform particle sizes improves product bioavailability and stability.

![]() Ultra-high pressures to 60,000 psi (4200 bar) and processing from Lab R&D scale to volumes over 2000 l/hour.

Ultra-high pressures to 60,000 psi (4200 bar) and processing from Lab R&D scale to volumes over 2000 l/hour.

![]() Easy-to-scale systems provide consistent, repeatable results.

Easy-to-scale systems provide consistent, repeatable results.

![]() Multiple options for temperature control, including pre-heating and rapid post-process cooling.

Multiple options for temperature control, including pre-heating and rapid post-process cooling.

![]() A choice of both Micro channel (interaction chambers) and piston gap processing configurations for optimized processing.

A choice of both Micro channel (interaction chambers) and piston gap processing configurations for optimized processing.

![]() Easy to use, sterilize and maintain. Low ongoing ownership costs.

Easy to use, sterilize and maintain. Low ongoing ownership costs.

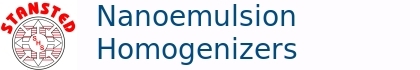

Flow rates from 1ml to 275ml per minute / 16 L per hour and a wide range of sample sizes from 1m to 32ml.

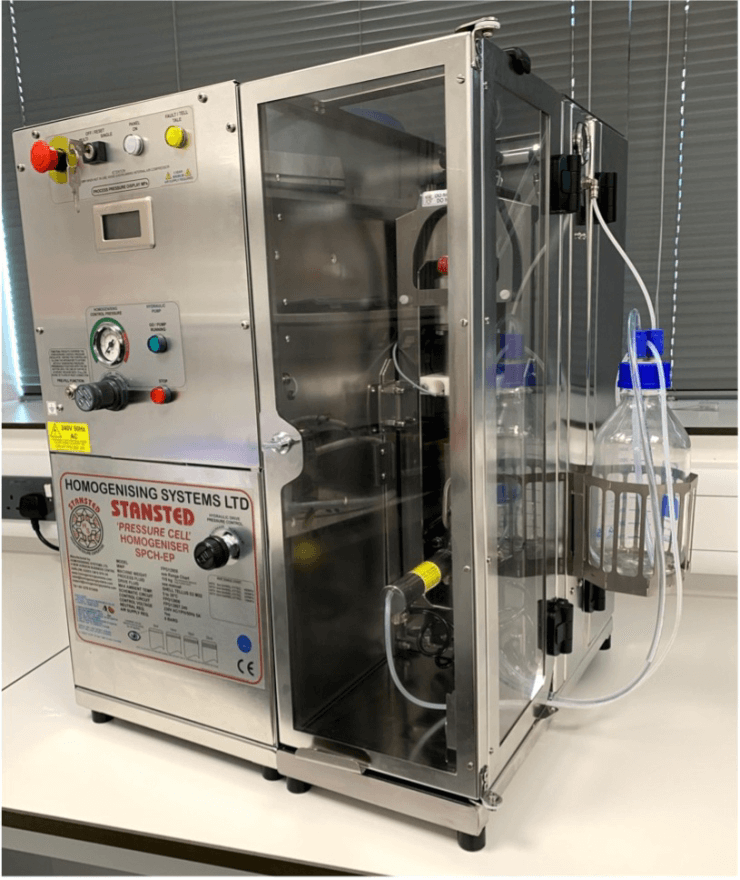

Pilot - Smaller scale production

Reliable and robust systems up to 125 l/h.

Production Homogenizer systems

Fully featured Production systems with flow rates up to 2000 l/h.

Application notes - Nanoemulsion formulation - the STANSTED High-Pressure Homogenizer

This test used our versatile SPCH Lab homogenizer (see image above). The emulsion formulation was pre-heated and stirred immediately before it was pumped into the Homogenizer. Pre-heating is not often required, but it was part of the specification in this test.

NOTE - We offer multiple options for temperature control: cooling before processing, rapid cooling at the homogenizer's exit point, and pre-heating (often used when processing liposomes / SLNs)..

This test aimed to formulate a nanoemulsion with particle sizes ranging from 50nm to 80nm.

Multiple tests were undertaken at different pressures, and one or two passes through our STANSTED Homogenizer.

The objective was reached quickly using the following processing parameters:

![]() The sample was processed using our Piston Gap technology at 2500 bar / 36,000 psi / 250 MPa.

The sample was processed using our Piston Gap technology at 2500 bar / 36,000 psi / 250 MPa.

![]() We tested one pass and two passes, which yielded slightly better results. On other formulations, we have found one pass to be sufficient.

We tested one pass and two passes, which yielded slightly better results. On other formulations, we have found one pass to be sufficient.

![]() The emulsion sample was pre-heated and gently stirred before processing.

The emulsion sample was pre-heated and gently stirred before processing.

The processing parameters above reduced average particle sizes to 50nm - so reaching the test objectives. Even lower particle sizes can be achieved in different scenarios.