Nanoencapsulation has increased because of its unique features for efficient encapsulation, enhanced stability, and better-controlled release of the enclosed active ingredients, such as drug delivery to the diseased site.

Nanoencapsulation - Our High-Pressure Homogenizers

![]() Precise high shear creating smaller, target particles with uniform particle distribution with repeatable results.

Precise high shear creating smaller, target particles with uniform particle distribution with repeatable results.

![]() Scalable systems, from Lab instruments to complete production systems, can help produce a very high number of doses.

Scalable systems, from Lab instruments to complete production systems, can help produce a very high number of doses.

![]() High-pressure fluid processing at industry-leading pressures up to 60,000 psi (4200 bar).

High-pressure fluid processing at industry-leading pressures up to 60,000 psi (4200 bar).

![]() Sophisticated temperature control options.

Sophisticated temperature control options.

![]() CIP and SIP capability. Full documentation packs and provision of DQ/IQ/OQ.

CIP and SIP capability. Full documentation packs and provision of DQ/IQ/OQ.

![]() Easy to use, sterilize and maintain with low ongoing ownership costs.

Easy to use, sterilize and maintain with low ongoing ownership costs.

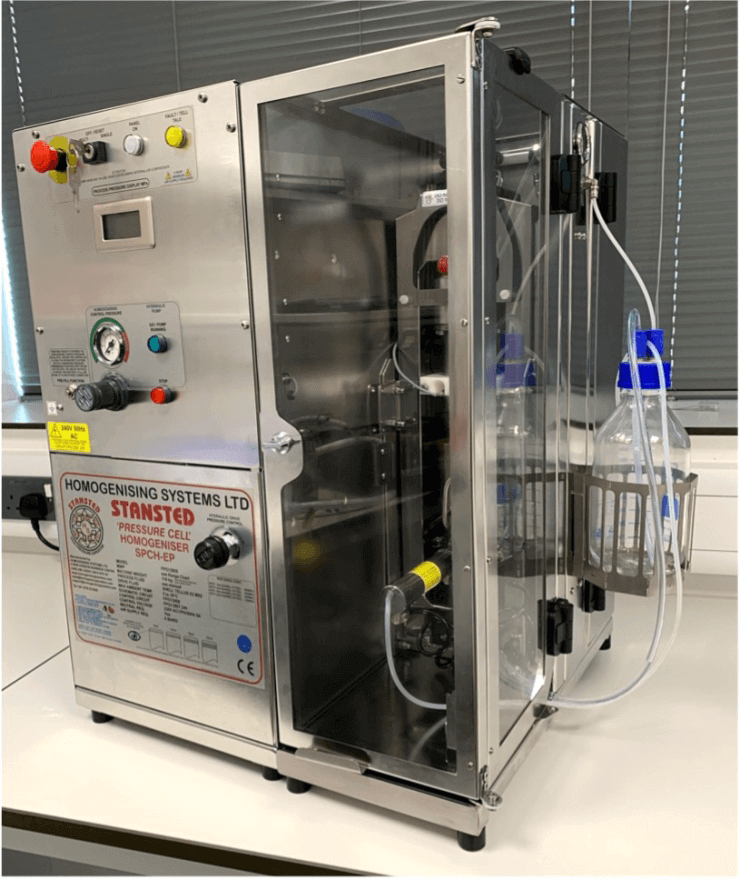

Lab scale Homogenizer

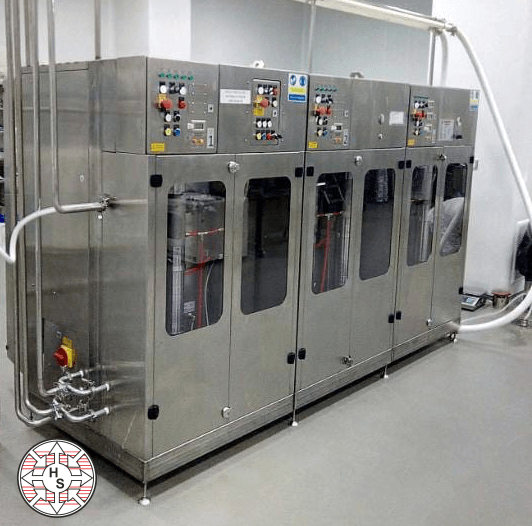

Pilot Production system in a Pharmaceutical project with feed and discharge reservoirs

Larger scale Production system