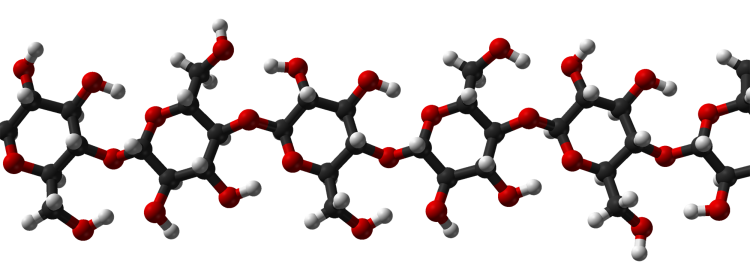

Polysaccharides are long chains of monosaccharides linked by glycosidic bonds. They are both biodegradable and biocompatible. Polysaccharides are used increasingly in the development of pharmaceuticals, including as carriers for water-insoluble drugs, plasma expanders, immune stimulators and vaccine antigens.

Polysaccharides - our High Pressure Homogenizers

![]() Benefits may include reduced viscosity, low polydispersity, higher solubility at a neutral pH, and easier post-processing purification.

Benefits may include reduced viscosity, low polydispersity, higher solubility at a neutral pH, and easier post-processing purification.

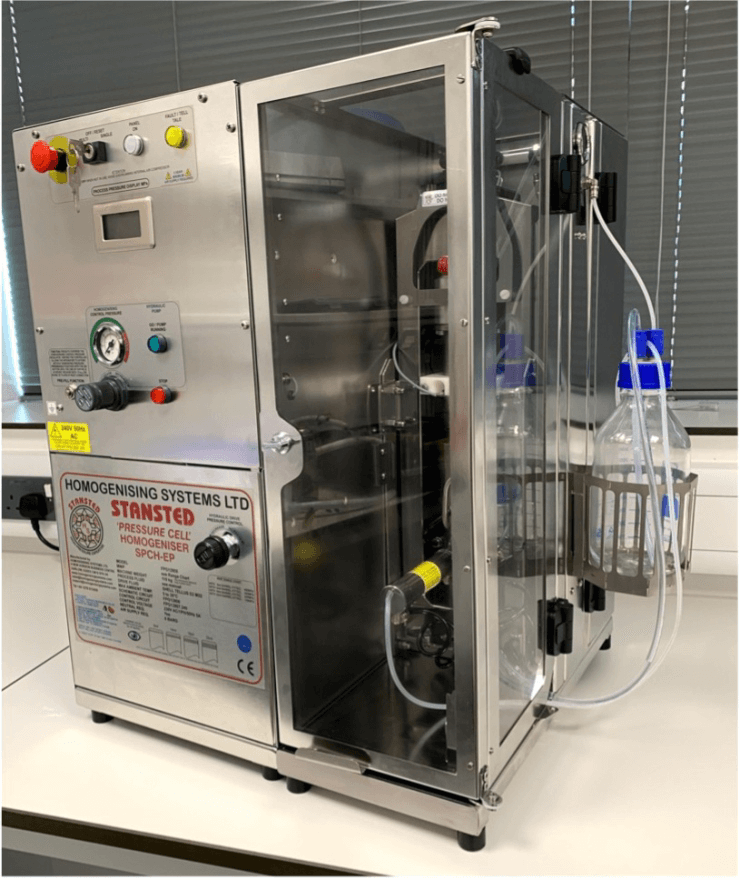

![]() Industry-leading pressures of up to 60,000 psi (4200 bar), and processing from 1 ml to in excess of 2000 l/h.

Industry-leading pressures of up to 60,000 psi (4200 bar), and processing from 1 ml to in excess of 2000 l/h.

![]() Multiple options for temperature control, including pre-heating and rapid post-process cooling.

Multiple options for temperature control, including pre-heating and rapid post-process cooling.

![]() CIP and SIP capability and provision of DQ / IQ / OQ.

CIP and SIP capability and provision of DQ / IQ / OQ.

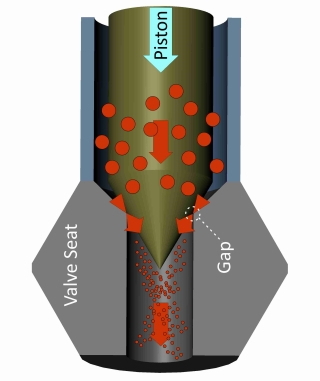

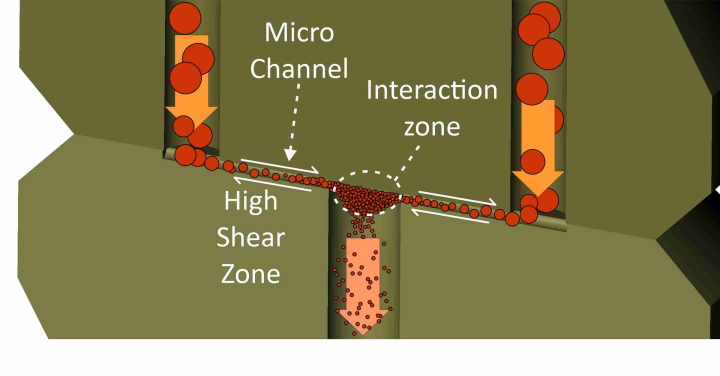

We offer interchangeable piston gap (PG) and microchannel devices (MCD) processing heads for our homogenizers - see below.

Pilot - Production Homogenizing System

Lab scale Homogenizer

Please get in touch to discuss your requirements.

Piston Gap and Micro-Channel Device ('interaction chamber').

3D structure of cellulose, a beta-glucan polysaccharide - Wikipedia