UHPH - Sterlization - Presevation

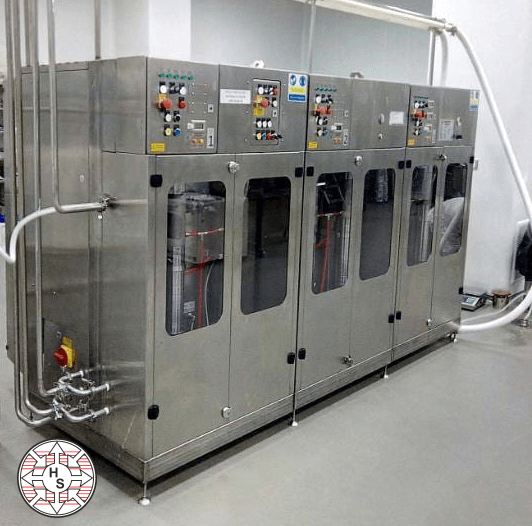

Also referred to as 'Presevation' this mechanical technology with applications mainly focused on the continuous treatment of fluid food products.

Our industry-leading systems provide the simultaneous homogenization and sterilization and of fluid products / beverages without causing any damage to their original properties.

Our UHPH technology - Features and Benefits

![]() Product shelf-life extension through the inactivation of microorganisms and improvements in functionality due to increased emulsion capacity and stability, with minimal effects on nutritional value.

Product shelf-life extension through the inactivation of microorganisms and improvements in functionality due to increased emulsion capacity and stability, with minimal effects on nutritional value.

![]() Sophisticated temperature control systems, enabling pre-cooling or pre-heating, post-cooling and maintaining the process section at a constant temperature.

Sophisticated temperature control systems, enabling pre-cooling or pre-heating, post-cooling and maintaining the process section at a constant temperature.

![]() Power consumption is typically lower than other processing technologies so a reduction in production costs is possible.

Power consumption is typically lower than other processing technologies so a reduction in production costs is possible.

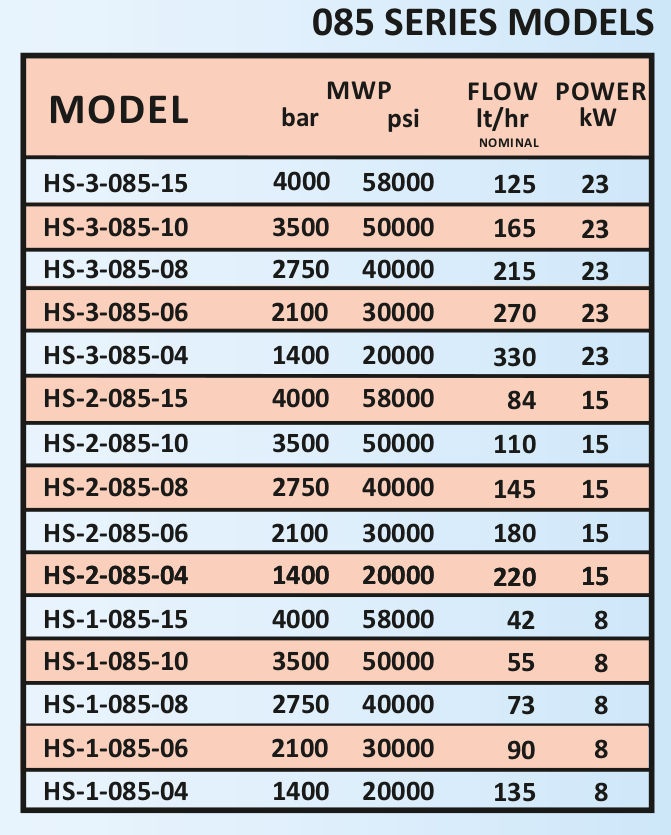

![]() Flow rates to 1000 l/hr (264 US Gallons/hr).

Flow rates to 1000 l/hr (264 US Gallons/hr).

![]() Easy to operate, clean and service. Versatile and robust.

Easy to operate, clean and service. Versatile and robust.

![]() Industry-leading ultra high pressures up to to 60,000 psi (420 MPa, 4200 bar).

Industry-leading ultra high pressures up to to 60,000 psi (420 MPa, 4200 bar).

![]() Processing options of piston gap valves and micro channels (interaction chambers) to ensure optimised and customised processing to suit the application.

Processing options of piston gap valves and micro channels (interaction chambers) to ensure optimised and customised processing to suit the application.

![]() Twin synchronised intensifiers for continuous smooth operation and consistent processing.

Twin synchronised intensifiers for continuous smooth operation and consistent processing.

![]() CIP and SIP capability.

CIP and SIP capability.

Contact us here to discuss your requirements.