Adjuvants are commonly utilised to enhance the efficacy of a vaccine and thereby help increase the resulting immune response in a patient.

Our industry-leading technology can create nanoparticles with controlled droplet sizes and distribution curves that can be sterile-filtered with minimal yield losses.

Vaccine adjuvants - our STANSTED High Pressure Homogenizers

![]() Easy to scale up - from Lab R&D to full production systems - up to 2000 l/h - with repeatable results.

Easy to scale up - from Lab R&D to full production systems - up to 2000 l/h - with repeatable results.

![]() Controllable, industry-leading pressures up to 4200 bar (60,000 psi / 420 MPa).

Controllable, industry-leading pressures up to 4200 bar (60,000 psi / 420 MPa).

![]() Multiple options for temperature control, including pre-heating and rapid post-process cooling.

Multiple options for temperature control, including pre-heating and rapid post-process cooling.

![]() CIP and SIP capability. Provision of DQ / IQ /OQ documentation.

CIP and SIP capability. Provision of DQ / IQ /OQ documentation.

![]() Easy to clean and sterilize.

Easy to clean and sterilize.

![]() Easy to maintain with low ongoing ownership costs.

Easy to maintain with low ongoing ownership costs.

![]() Precise high-shear creates smaller target particles with a narrow size distribution..

Precise high-shear creates smaller target particles with a narrow size distribution..

Lab Homogenizer for Vaccine R&D

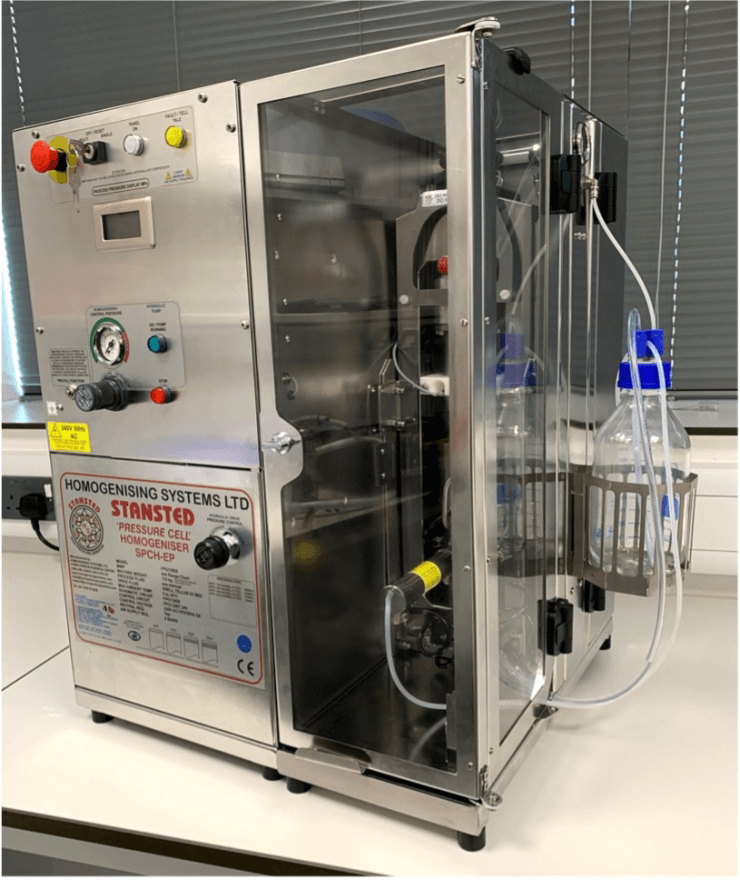

Pilot Homogenizer in a Pharmaceutical project with feed and discharge reservoirs

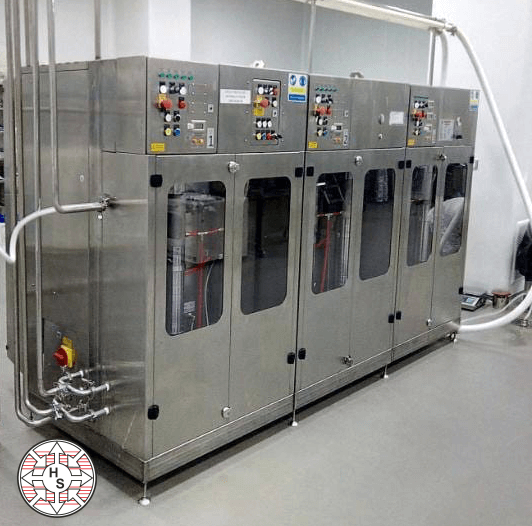

Production Homogenizer system